Milling machines are one of the most common pieces of machinery using across many different industries for hundreds of different purposes, with different designs, compatibilities and functionalities. In our first “back to school” feature, we explain what a milling machine is, how they work and how purchasing one from Ward Hi Tech today can benefit your business

What are Milling Machines?

Milling machines are a type of machinery for removing material from a workpiece using rotary cutters. These machines can drill, bore, and cut an array of materials. This process of removing pieces of the material in line with the tool axis is known as milling, and thus the machines used in the process are called milling machines. Milling machines come in many types and are used across a variety of industries.

How Milling Machines Work

In many ways, milling machines are used to achieve similar results to lathes. However, unlike lathes which rotate the workpiece, milling machines hold the workpiece still using a vice or fixture. Milling machines use cylindrical tools such as drills and end mills to remove material. Milling machines are primarily used on flat surfaces though can work with some irregular surfaces too.

Types of Milling Machines

Milling machines come in many forms including column, turret, c-frame, horizontal tracer controlled, bed type and planer-style. These machines can be manual or CNC (computer numerical control). CNC milling machines are computer automated versions of the manual milling machines.

Column Milling Machines

Often used for creating car parts, a column milling machine is one of the simplest types of milling machine. They consist of 5 key parts the worktable, head, saddle, knee, and over arm and use a vertically suspended drill.

Turret Milling Machines

A turret machine is a versatile milling machine which can be used in the creation of many parts. Also, known as a Bridgeport-type milling machine, these machines can be repositioned opening a broader range of uses.

Horizontal Milling Machines

Named as it is positioned horizontal to the ground, horizontal milling machines work by moving the bench the workpiece is placed on sideways whilst the cutting tool moves vertically.

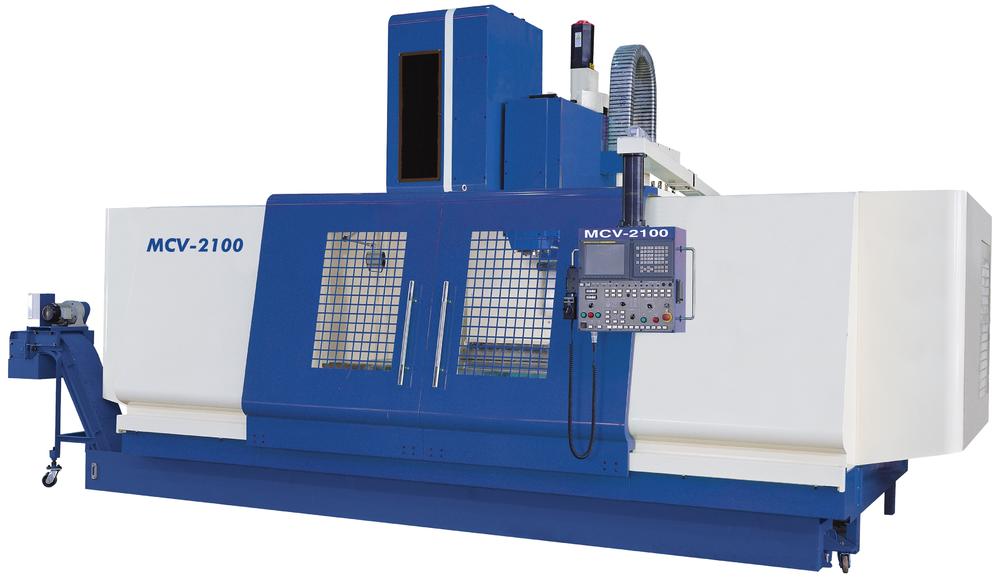

Bed Type Milling Machines

The worktable of a bed type milling machine is placed on the bed itself, as opposed to on top as with other milling machines. On a bed type machine, the knee is omitted to allow for longitudinal movement.

Who Are Milling Machines For?

As a leading machine for cutting metal, milling machines are widely used for making parts within the automotive and aerospace industries. Our milling machines can help you cut metal parts of all sizes in a quick and efficient manner, with easy to use controls

What brand of Milling Machines can you offer me and my business?

Our providers of Milling Machines are Dah Lih, Kiheung and Visionwide – for more information give us a call today on 0114-256-0333 and ask for Mike Burke.

Our Covid-secure offices in Sheffield are now open and we can give you a demonstration of what these machines can do.